Enhance Carrot Freshness with a Vacuum Cooler , Effective Cooling Solutions

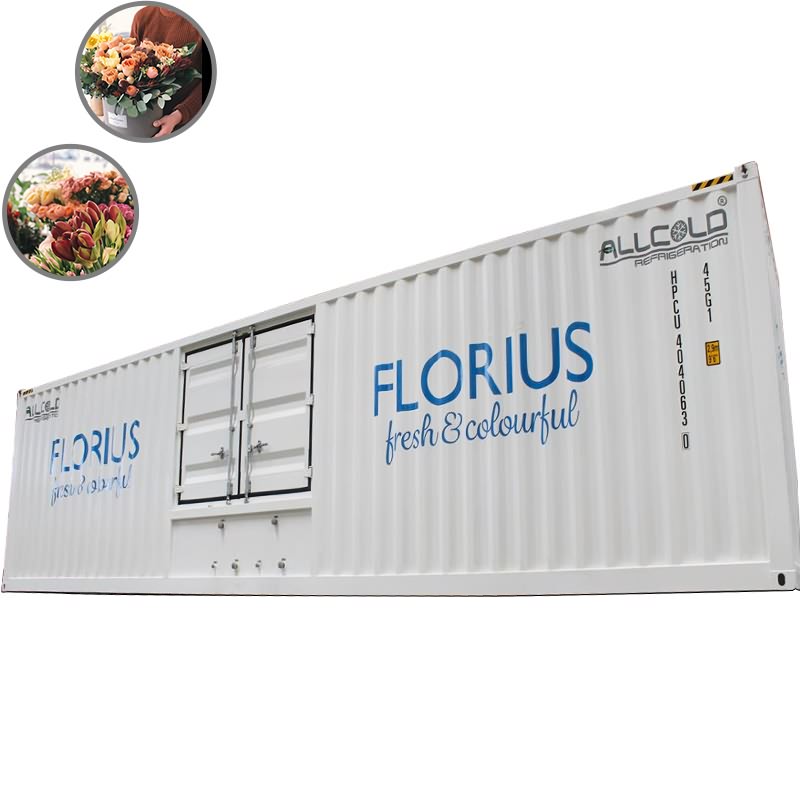

Introducing the Carrots Vacuum Cooler, brought to you by SHENZHEN ALLCOLD Co., Ltd., a famous manufacturer in the industry. This innovative cooling system is designed to streamline the process of cooling and preserving carrots, ensuring their freshness and extending their shelf life. The Carrots Vacuum Cooler utilizes advanced technology to rapidly lower the temperature of freshly harvested carrots, locking in their natural flavor, nutrients, and crispness. With its efficient and eco-friendly cooling process, this product is a game changer for carrot producers and distributors, allowing them to deliver high-quality produce to their customers while reducing waste and maximizing profitability. By partnering with SHENZHEN ALLCOLD Co., Ltd., a renowned leader in the field, you can trust that you are investing in a top-quality, reliable product that meets the highest industry standards. Experience the benefits of the Carrots Vacuum Cooler and elevate your carrot cooling and preservation process to a whole new level.

Related Products